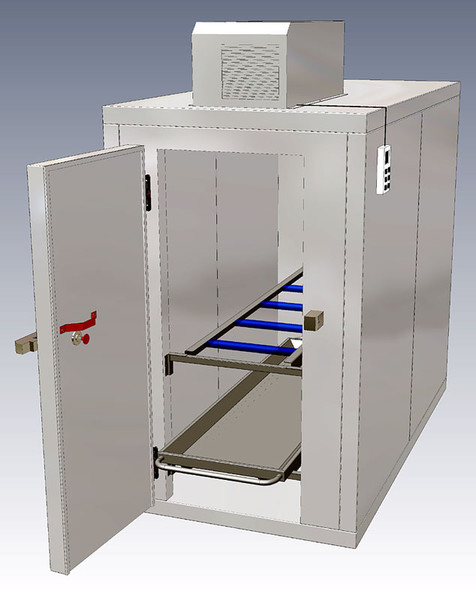

Two Bodies / Two Tiers – one large door mortuary refrigerator/Freezer(2 cadavers)

Thalheimer Mortuary refrigerators and freezers Multiple Tiers / Large Door LKZ GT / LKZT GT are produced with emphasis on modern technology, economic efficiency and German preciseness. Through continuous improvements in the manufacturing process, including the development and utilization of environmentally friendly, state of the art technologies, we have been able to significantly increase the refrigeration performance and efficiency of our products while dramatically reducing energy consumption.

Thalheimer Mortuary refrigerators and freezers Multiple Tiers / Large Door LKZ GT / LKZT GT are produced with emphasis on modern technology, economic efficiency and German preciseness. Through continuous improvements in the manufacturing process, including the development and utilization of environmentally friendly, state of the art technologies, we have been able to significantly increase the refrigeration performance and efficiency of our products while dramatically reducing energy consumption.

Insulation: Refrigerator: 80 mm polyurethane-foam / Freezer: 100 mm polyurethane-foam, both options are sufficient to maintain the specified internal temperature in the specified ambient conditions, with low heat transfer coefficient 0,240 W/m2K

Roller tracks: Per body one roller track with 5 rolls with maintenance-free ball bearings for an easy move of the tray in and out. At the rear side the roller

is produced with an additional stop-roll which prevents shocks against

the back wall. The rolls are made of corrosion resistant material, coated

with plastic material and have maintenance-free ball bearings; the rails

are completely made of stainless steel.

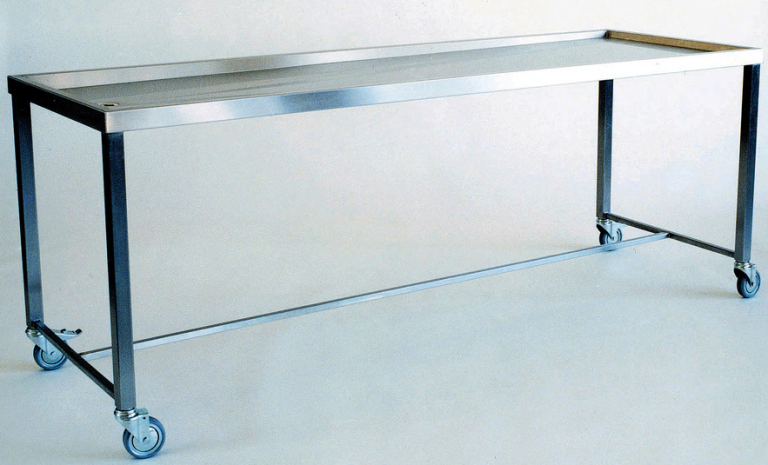

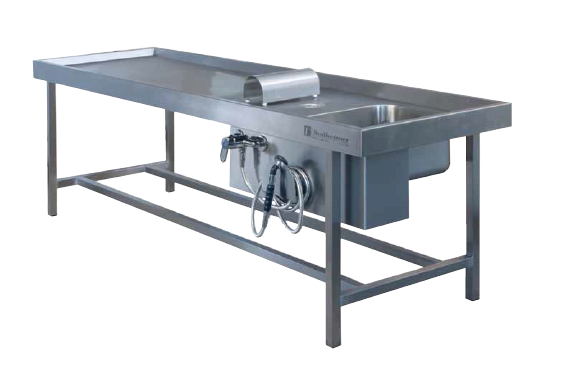

Body trays: Each mortuary refrigerator equipped with body trays, made of stainless steel quality 1.4301, seamless deep-drawn, rested on skids and at the small sides provided with bow handles, dimensions L x W x H = 2060 x 620 x 90 mm

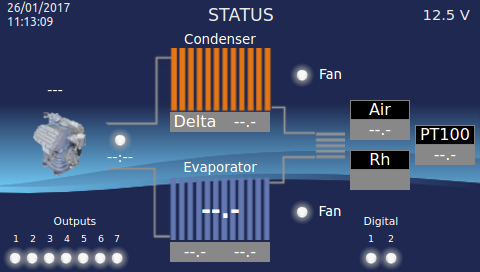

Cooling system: Can be mounted on the top panel, alongside the refrigerator or remotely (Split unit), the compressor is hermetically sealed, air-ventilated, vibration-free. The refrigerant used are of different types R134a or R404a or R507 CFC-free. Automatic time controlled defrosting, safety thermostat, microprocessor controller. As per customer’s requirement Thalheimer can design and produce Mortuary refrigeration and freezing systems with double cooling system that can be mounted on top, on side, or remotely in a machine room or anywhere. The cooling system includes auto switchover. The calculation of cooling capacity for each unit is designed to perform at a maximum ambient temperature.

The double cooling system is usually designed with the following features:

Provide complete back up protection for the cooling system of the mortuary refrigerator or freezer. This cooling system designed to contain two complete refrigeration units with duplicate condensing units and evaporators (fan coil). Each of these systems is enough to cool the cooling chamber independently. So if one fails for any reason the other takes over automatically to maintain the required internal temperature The system has a timer that alternates the two refrigerator system, running over for a pre-set period of time, enhancing the life of the system. (i.e. operational and resting on regular basis). The evaporators are of high-powerful type installed in the interior of the mortuary refrigerator, switched off / on from the control panel or (optional) if the doors are opened / closed (activated with a door-contact switch).

Condensation water drainage:

Drainage piping from evaporator to the floor drain through bottom panel or side

panel is possible, interior evaporation of condensation water is also possible.

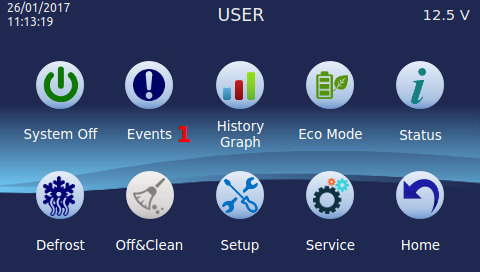

Alarm system: Visual and acoustic signaling at temperature instability, voltage 230 V or batteries, can be connected to remote alarm control through potential-free terminal. In case of double cooling system, each unit includes central alarm system, microprocessor-controlled, with optical and acoustical signals. The front side of the refrigerator is supplied with control panel which contains digital indication displays with 0.1 C resolution for internal temperature, audio and visual alarm for high temperature, temperature regulator, temperature recorder with (Optional) paper discs and internal light switch. The control system includes high-low pressure cut out, oil pressure cut out units, operation timers, defrost timers, and all other major elements.

Electrical system: The cooling systems produced for connection to power supply of 230/240 or 380 V, 50-60 Hz-1 ph-3ph. The supply includes power plugs and 3 m long power connecting cords, for connection to local power sockets.